A COLLABORATION WITH FTI INTERNATION AND ECT.

Over time most tanks will have a build-up of sludge, debris, contaminants, and water. Cleaning the inside of an industrial tank carries multiple risks and safety concerns. Cleaning out sludge or scale can often release trapped vapor, which is likely to be flammable and could lead to a chain reaction that results in venting large amount of gas to the atmosphere. The risk of fire & explosion, chemical and physical hazards, oxygen deficiency, microbiological presence, and emissions as a result, can be highly harmful & costly to mitigate. Hence, regular cleaning and inspection is crucial and necessary to ensure regulatory compliance and tank re-certification purposes. However, conventional cleaning & inspection methods via confined space entry can be highly challenging and hazardous for human intervention, requiring tanks to be shut down for long periods.

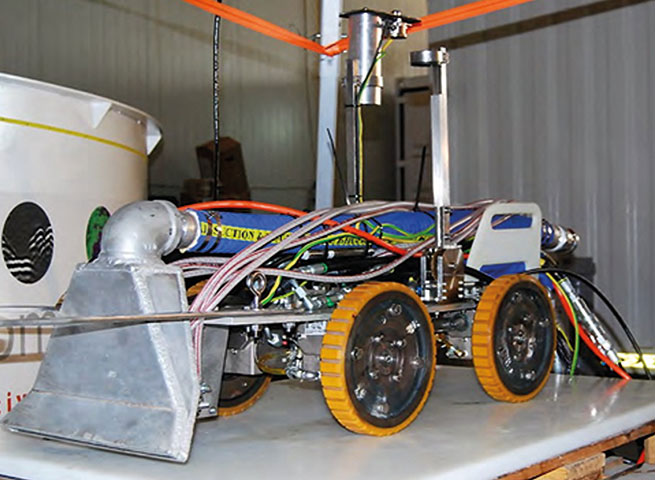

Therefore, in collaboration with FTI, a member of CWL Group and sister company of Sonomatic, IEV is launching the Tank In-Service Cleaning and Inspection Solutions (TICIS). FTI has provided TICIS for more than 700 worldwide, and is the leader in the field of designing and building robotic crawlers which can be used to clean and inspect tanks with no man entry.

To complement the robotic tank cleaning service, IEV, in partnership with ECT, the Malaysian-based developer and manufacturer of Bio-Solv, provides a sludge treatment solution using a water-based and biodegradable surfactant that can break down the hard sludge into liquid which can be pumped out by robotic crawlers for subsequent sludge oil recovery. Unlike conventional practices, this online cleaning and waste processing eliminates the need for shutdown while allowing tank operators to generate revenue from the oil recovery, as opposed to incur cost to discharge sludge.

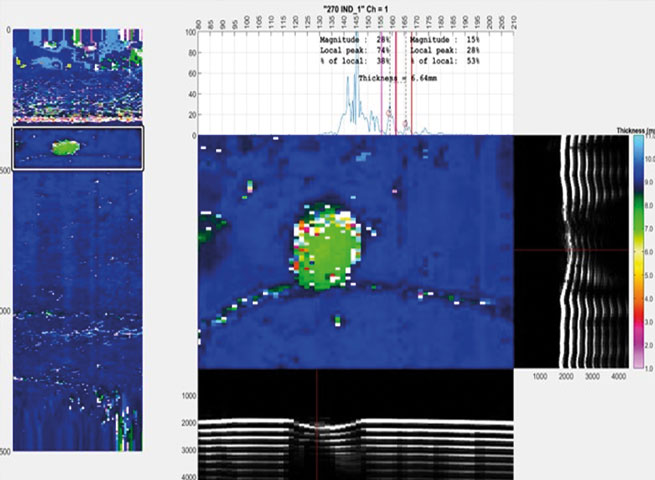

The in-service tank inspection offers sonar scan along a pre-planned path to perform a quantifiable UT inspection of the tank floor according to API 653. Integral to the inspection solution is the application of Fran-Scan (AP), which is a combination of zero-degree UT, SRUT/ GW (Short Range/ Guided Wave) and PAUT (Phased Array) for the inspection of annular plates and the critical zone of storage tanks. The annular plate can be screened up to 750-1000 mm with SRUT. With the addition of A-ring application, detection and quantitative measurements can also cover the critical zone up to 100mm from the inner shell wall. Complimented with other phased array applications, the quantitative measurements up to 150-200mm is achievable.

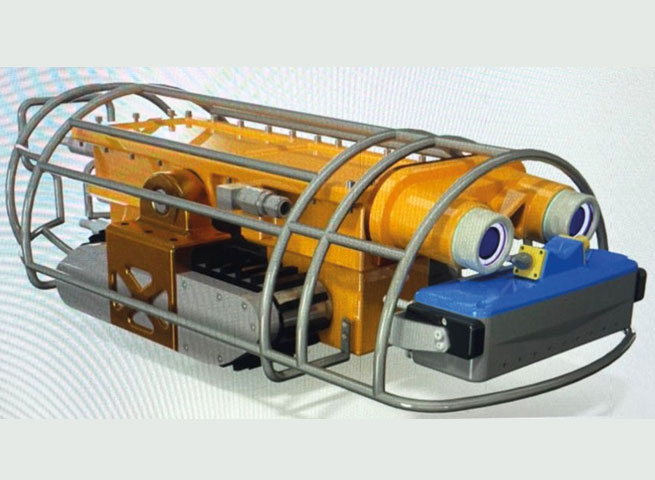

The operation can also include underwater drones/ mini ROV for fire water tanks for the visual inspection on the inner tank shell wall and bottom plate, to detect general wall loss, sediment levels, visible cracks, erosion, or any other visible anomaly.

Upon field inspection, screening results or field data are reviewed, analysed, and reported with statistical analysis following API 653 standard, to predict the minimum thickness of the tank floor area, and the calculations of Fitness-For-Service and Remaining Life Assessment, as well as the recommended inspection frequency.

For further information contact us at info@iev-group.com for your specific tank cleaning and inspection solutions.