Asset Integrity Management

We offer a range of disruptive technologies as an individual services or integrated engineering solutions to deliver optimum and cost-effective solutions to inspect, assess, repair and maintain assets.

COLD CUTTING

- A suite of cold cutting technologies for various structures and pipeline specification

- Can be deployed for subsea and above water applications

REHABILITATING ASSETS THROUGH REVOWRAP COMPOSITE REPAIR

- An engineered composite solution to restore damaged critical assets to the original design specification of the equipment.

- Stronger than steel

- Designed for 225oC operating temperature with no pressure limitations and fast curing.

Info Pack

STRUCTURAL STRENGTHENING

- Strengthening structure through grouted clamps or tubular grouting

- Small footprint of a low-cost mixer and small crew size

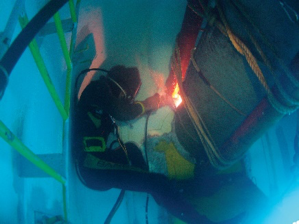

UNDERWATER DRY WELDING SOLUTION

- Repair solutions for damaged subsea structures using habitat dry welding method

- Underwater repairs for damages such as dents, tears, holes, cracks, parted boat lading supports, etc.

- Subsea Installation new structural members

- All UDW are pre-qualified and repairs are certified by third party agency

- Over 10-year of track record

Info Pack

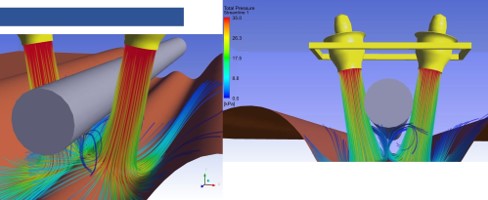

ROTECH SUBSEA TRENCHING & EXCAVATION

- The Rotech Subsea (RS) is a suite of highly effective subsea excavation tools deployed over the side of a vessel and operated remotely from its deck.

- The technology is based on the principles of producing a controlled column of water, the pressure of which fluidises the seabed and effectively excavates a trench.

- It is a non-contact system which minimises the risks associated with physical contact especially around complex subsea assets.

- The Trenching and Excavation Equipment, operated by Rotech Subsea, is designed by Rotech Engineering and built in-house.

Some of the common applications include:

- Cable Array and Export Trenching / De-burial

- Cable Joint Burial / IRM

- Pipeline, Umbilical & Flowline Trenching / De-burial / Recovery

- Backfilling for Cable / Pipeline Protection

- Jack-up Leg / Spud Can Clearance

- Harbour / Pontoon Seabed Clearance

- Sandwave Clearance / Cable & Pipeline Route Clearance

- Salvage De-burial / Access

- Access to Subsea Structures / IRM / Decommissioning

- Drill Cuttings Removal

- Rock Removal / Relocation & Dispersal

Info Pack

RUBBER ENGINEERING, AND HEAVY FABRICATED PRODUCTS IN THE MARINE AND OFFSHORE INDUSTRIES

Specialising in rubber engineering and heavy fabricated products for the marine and offshore industries, IRM delivers solutions built for durability and high performance across a variety of sectors, backed by decades of expertise.

Key Products and Services:

- Marine Fenders: A comprehensive range of fenders, designed to protect vessels from small boats to large tankers.

- Floating Fenders: Advanced anti-collision devices for smooth ship-to-ship and ship-to-dock operations.

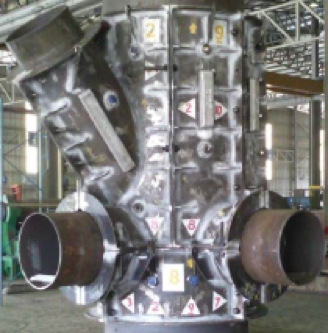

- Offshore Products: Critical components such as pile grippers, leg mating units, and deck support systems for offshore platforms.

- Boat Fenders: Customizable fender solutions for small boats, yachts, and other marine vessels.

- Dock Accessories: Essential items including bollards, ladders, buoys, and edge protectors to enhance safety and functionality at docks.