Asset Integrity Management

We offer a range of disruptive technologies as an individual services or integrated engineering solutions to deliver optimum and cost-effective solutions to inspect, assess, repair and maintain assets.

Advanced Inspection Solutions

We offer an array of Qualitative and Quantitative techniques to optimize your inspection program. Our unique combination of technologies allows for customized solutions to meet client’s inspection requirement, budget and standards.

Categories of Inspection

- Non-Piggable Pipelines

- CUPS Inspection

- CUI Inspection

- Composite Wrap Inspection

- Jacket Inspection

- Splash Zone Inspection

- Hard To Access Areas

Info Pack

Skipper NDT

A drone-based platform that acts as a Modern Solution for Locating and Mapping Below Ground Pipelines to Acquire Depth of Cover, Water Crossings, and Bending Strain Data.

Skipper NDT is a purpose-built tool to address current technology limitations.

FEATURES AND BENEFITS :

Surface Measurements

Patented Hardware

- Electronic card development for real-time data processing and storage

- Component selection for minimal magnetic interference (nanotesla level) that ensures the drone’s sensors and navigation systems operate accurately and reliably.

Magnetometer Compensation

- 25 X precision improvement compared to native performance

Location Detection

Field Data Level Control

- Magnetometer movement compensation to ensure accurate and optimal signal processing for navigation and orientation purposes

Interference Filtering

- Algorithm able to be clean the signal from any exterior interference for a more accurate data processing. (high voltage lines etc…)

DECISION SUPPORT

Pipeline Detection Algorithm

- Several algorithms to detect and locate the pipeline

SaaS Platform for Data Restitution

- Output adaptable to client’s Global Information System Data Format

- Four tri-axial fluxgate magnetometers

- Real-time Global Navigation Satellite System GNSS receiver with a centimetric-level accuracy

- Tactical grade inertial measurement unit (IMU)

- Telemetric sensors measuring the distance between the magnetometers and the ground (or canopy)

- Proprietary electronic card for data acquisition, digitalization, and synchronization

Skipper NDT value to determine Depth of Cover

- Lower Risk

- Safety First

- Dense Data

- Time Efficient

- Easy Logistics

- Time Efficient

Skipper NDT value to determine Bending Strain Assessment

- Easy deployment

- Time Efficient

- Cost Effective

Info Pack

SPECTRUM XLI

(ABOVE GROUND INSPECTION OF BURIED PIPELINES)

- Indirect Inspection Technology collecting Multiple Sources of Data (GPS/GIS, depth of cover, depth of water, gas leak detection, cathodic protection survey (CP CIPS/CIS), direct current voltage gradient (DCVG), alternating current voltage gradient (ACVG), alternating current-current attenuation (ACCA), and soil corrosivity measurements in a Single (1) pass.

- All measurements are Encrypted Raw Logs and can be audited upon pipeline owner’s request.

- Data collected accessible to External Corrosion Direct Assessment (ECDA), Internal Corrosion Direct Assessment (ICDA), Stress Corrosion Cracking Direct Assessment (SCCDA), Cathodic Protection (CP) and Close Internal Surveys (CIS).

- Post analysis and reporting of inspection results are completed by NACE Certified CP and Corrosion Specialist.

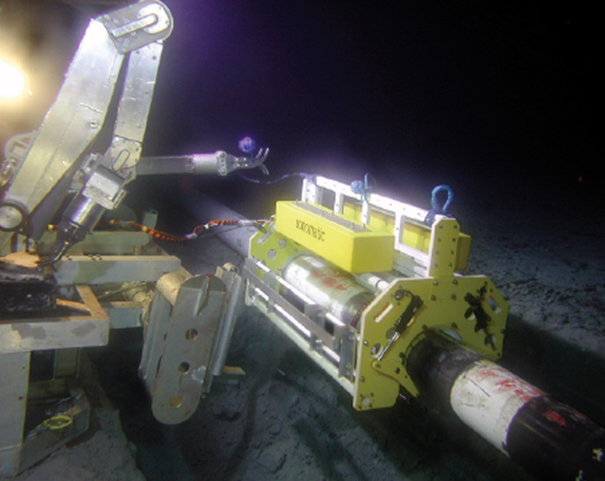

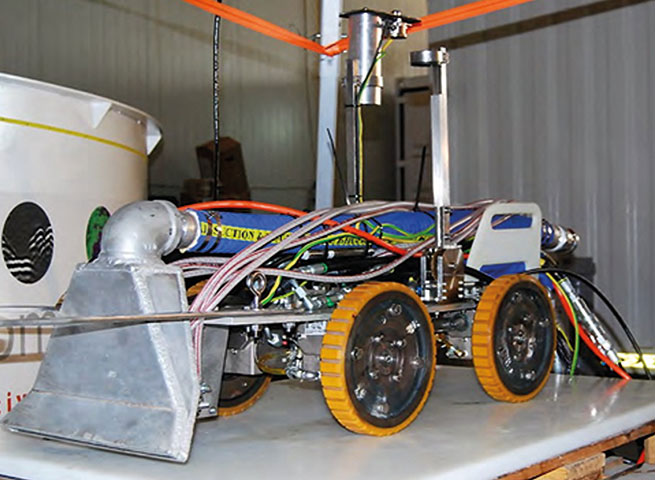

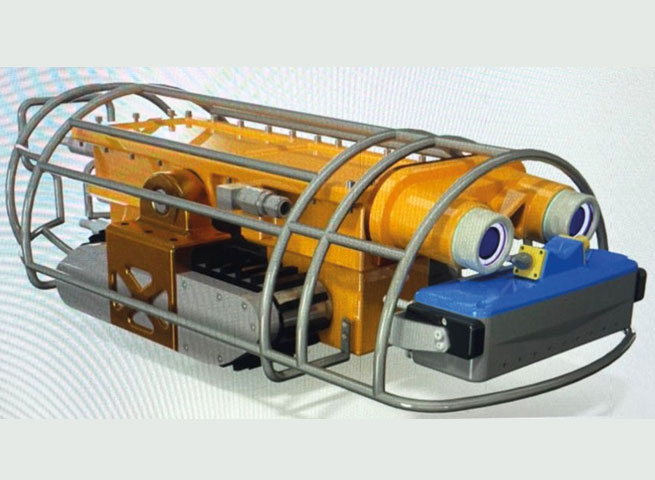

TANK IN-SERVICE CLEANING & INSPECTION SOLUTIONS (TICIS)

WHAT IS TICIS ?

- Tank In-line Cleaning and Inspection Solutions is the use of robots to carry out tank cleaning and inspection with no man entry or product removal required.

TICIS : Our Services

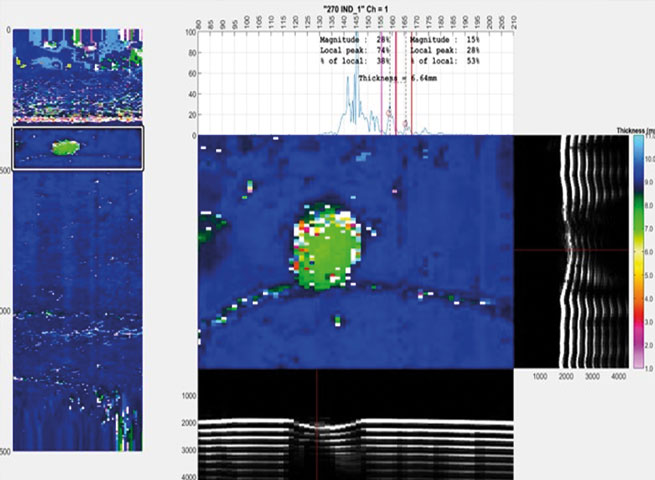

TANK IN-SERVICE IN-SERVICE INSPECTION

- FRANSCAN for annular plate inspection

- Internal tank base robotic inspection techniques

- Internal visual of tank walls, roofs and support

- Probabilistic analysis and reporting

CLEANING ROBOTS

- Hydraulic Robot For Class 1, Crude, Condensate Etc

- ATEX Robot For Low Sludge Applications

- Class 2 Fuels And Non-volatile Tanks

SLUDGE OIL RECOVERY

- Non-Manned cleaning of sludge at tank bottoms

- Sludge Fluidisation methodology